Beyond the Floor

June 2023 - November 2023

Teammates

Seo Young Choi

Gahyeon Kim

Heejin Kim

Punn Lertjaturaphat

Background

Producing wooden floor tile create more then 10 tons of byproduct waste in each year. Moreover, 12 tons of the final product ended up failing the quality control procss.

Upcycling product is good for expanding the lifetime of the material but, eventually, they inevitably ended up in the landfill.

We believe that true upcycling is reusing the material multiple times, and gradually decompose the product back to nature with minimum waste produce in different forms.

"How can byproducts and wooden flooring that fail quality control (QC) be transformed into effective upcycled products and services within a sustainable system?"

While existing upcycling products simply focus on creating new products, we aim to create designs that “consider the product’s final journey.” thinking about how the products can be decomposed back to nature.

We considered these design goals for our effective upcycling

- Has the potential to be upcycled multiple times.

- Avoid incineration disposal.

- Has multiple uses.

- Increases the value while its properties gradually return to nature.

Waste should not be irreversibly processed.

Decomposition

Mycelium is the vegetative structure of a mushroom — equivalent to the roots, stems, and leaves of ordinary plants — and forms the main body of the fungus, appearing as white, cottony fibers or thread-like strands.

In an ecosystem, mushrooms act as decomposers that support material cycling. Among the many organisms that perform decomposition, they play a central role, particularly excelling at breaking down plants and wood.

Because breaking down wood is both “disposing of it well” and also an opportunity for it to transform into a “new material to be used once more,” We cultivate mycelium on discarded flooring wood and use the processed mycelium-based material in our design.

Cultivating Mycelium Using Discarded Flooring

By injecting mycelium into byproducts from the flooring manufacturing process—such as sawdust—and providing sufficient nutrients, the mycelium is grown for its initial stage. It is then placed into a shaped mold for a second growth phase, and finally heated to produce a finished mycelium block.

This significantly shorten the time to decompose the byproduct waste and making it easier to return to nature.

Product

Drawing inspiration from how the floor is part of the people’s personal life, we decided to design furnitures that integrate themselves into people’s lifestyle.

My.10

A stool

My.10 is a stool made from 10 pieces of flooring, a comfortable place for everyone to sit. People sit on the stool to read, make things, work, or engage in creative activities.

The V-shaped bottom of the stool can be used to store personal belongings.

My.08

A bench

My.08 is a bench made from eight pieces of flooring, designed for multiple people to sit together.

To encourage interaction among people, My.08 reduces both the physical and psychological distance between users, creating a foundation for communication.

Its V-shape is ergonomically designed to fit the natural contours of the body, allowing people to sit comfortably.

My.06

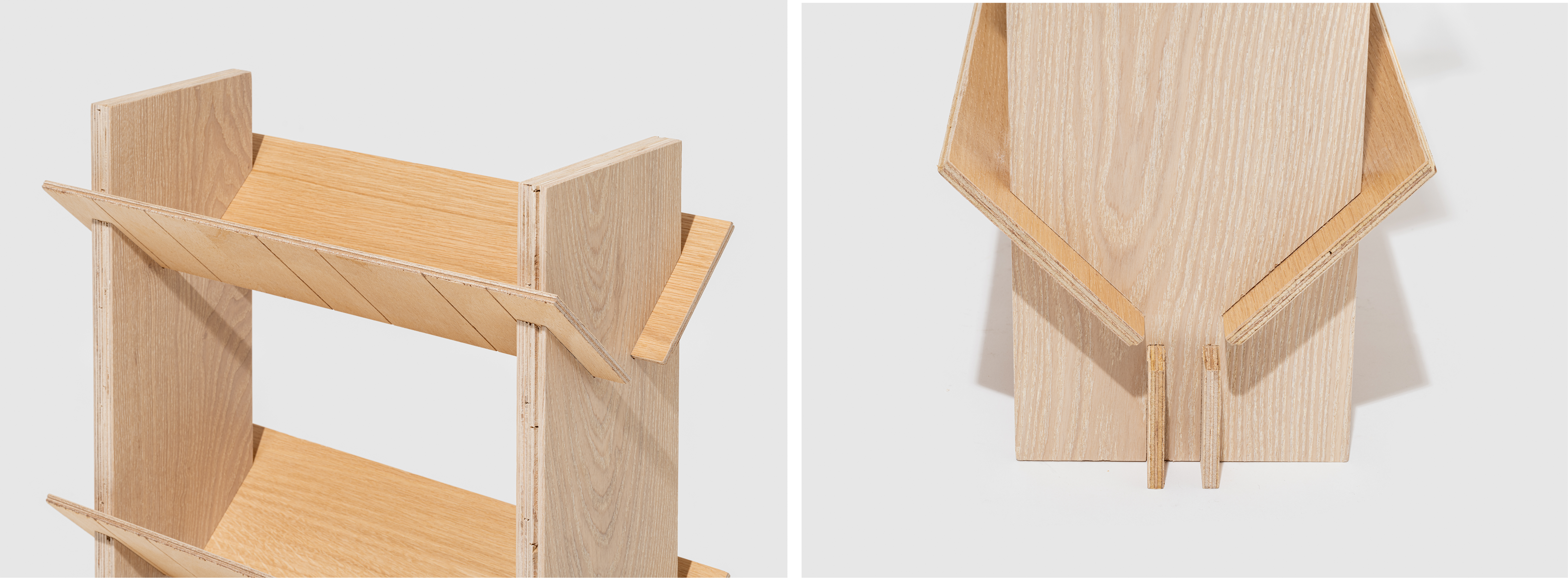

A bookshelf

My.06 is a bookshelf made from six pieces of flooring, designed to store books efficiently and securely.

The V-shape of the shelf distributes weight across a smaller surface area, allowing it to hold many books effectively.

My.00

My.00 is a book partition and planter designed to be used alongside My.06.

It is made from mycelium blocks grown using flooring sawdust, and when used as a planter, it can be planted directly into the ground along with the plant.

Features

Whole number material

To minimize byproducts generated during processing, we designed the furniture so that each piece uses a natural integer number of flooring boards. The stool uses 10 boards, the bench uses 8, and the bookshelf uses 6, resulting in almost no leftover scraps during production.

Minimizing use of adhesive

The furniture is made from flooring boards and mycelium. To ensure the flooring can be reused later as a substrate for growing mycelium, the pieces are assembled using a minimal amount of adhesive.

Additionally, instead of nails, a wood-wedge joinery method is used, creating a physically stable structure that can be disassembled and reassembled.

The adhesive used is the same non-toxic glue employed by Kujung Flooring during installation, ensuring safety and material recyclability.

Easy assembly

Designed so users can easily assemble and disassemble it without special tools, the furniture can be shipped in a flat-packed state, reducing carbon emissions during transport.

When users no longer need the assembled furniture, it can be taken apart and stored with ease. If any component is damaged, only that part needs to be replaced, and the damaged pieces can be recycled as material for producing new mycelium blocks.

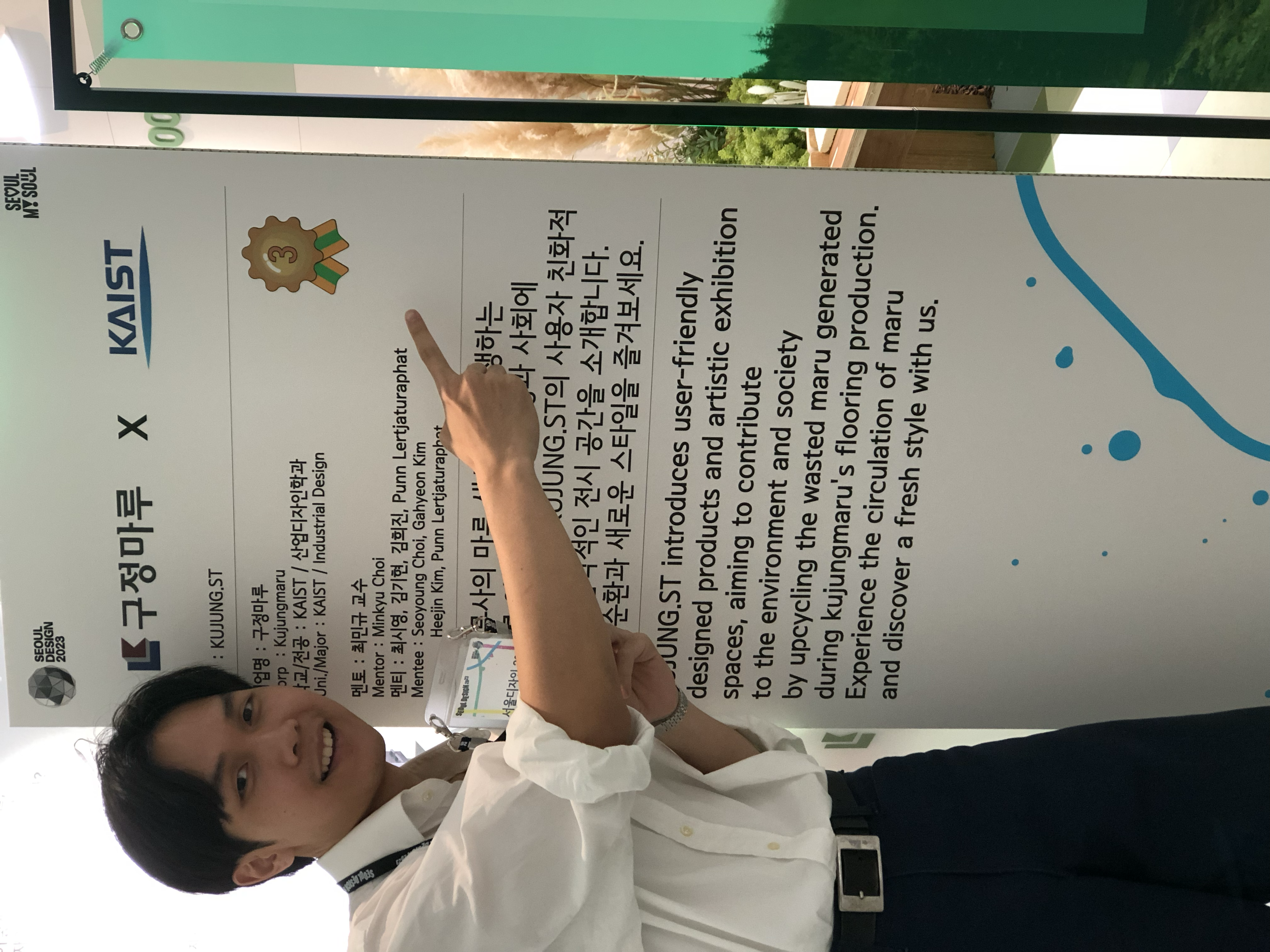

The Exhibition